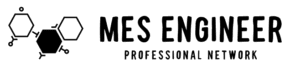

ISA-95, also known as the International Society of Automation standard, is a comprehensive framework that provides guidelines for integrating different systems and processes within the manufacturing industry. The standard focuses on improving communication, data exchange, and interoperability between various levels of an organization, such as the control level, operations level, and business level.

The ISA-95 standard is divided into a hierarchical model that consists of four levels:

- Level 0: The Physical Level

- This level represents the actual physical equipment and processes on the factory floor.

- It includes devices like sensors, actuators, and control systems that interact directly with the manufacturing process.

- Level 1: The Control Level

- At this level, the control systems monitor and control the physical processes.

- It includes operations like machine monitoring, data acquisition, and control of individual devices or equipment.

- Level 2: The Operations Level

- This level focuses on coordinating and managing activities across multiple control systems and departments.

- It involves functions like production scheduling, recipe management, and order tracking.

- Level 3: The Business Level

- The highest level of the ISA-95 model, it deals with enterprise-wide decision-making and planning.

- Here, functions such as resource allocation, production forecasting, and order fulfillment are carried out.

ISA-95 provides a common language and set of guidelines for data exchange and integration between these levels. It enables manufacturers to integrate different systems, improve efficiency, reduce costs, and make better business decisions based on accurate and real-time information.

By implementing the ISA-95 standard, manufacturers can achieve a more streamlined and coherent approach to their manufacturing processes, leading to increased productivity and competitiveness in the global marketplace.